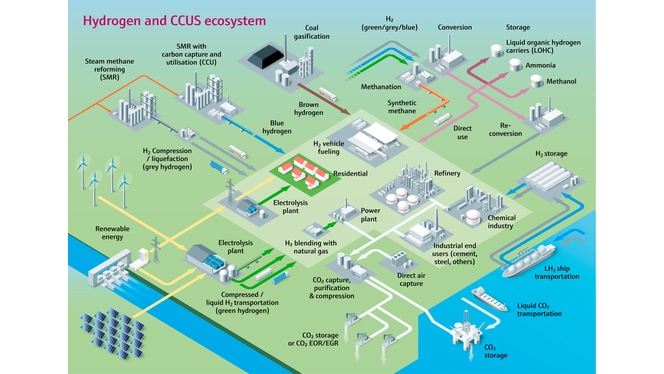

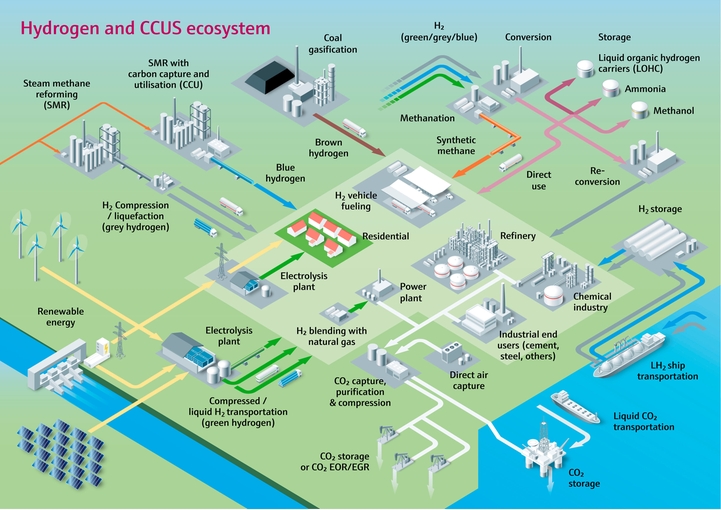

Accidents in process plants often have fatal consequences for the environment, people and the equipment. Endress+Hauser's extensive portfolio and expertise in process and functional safety help you to reduce, detect, and eliminate random or systematic failures. Given the nature of the gases and the risk for potential hazards, safety is paramount in hydrogen and CCUS applications across the value chain.

Klíčová fakta

USD 80 billion

average annual global investment in H2 infrastructure to increase tenfold by 2050 (IEA)

Hydrogen pressure measurement with gold-plated membrane

Pressure measurement in hydrogen applications presents a unique challenge due to permeation. In hydrogen gas service, molecules diffuse through the diaphragm surface of the pressure transmitter and form gas bubbles in the fill fluid. Since the pressure cell or diaphragm seal is a closed environment, this additional volume has no means of escape and thin 316L / Alloy C membrane becomes distended resulting in damage.

Our expertise in the field

Properly deployed gold coating is a cost-effective method to significantly reduce hydrogen permeation and extend the life of your pressure transmitter. By relying on Endress+Hauser pressure measurement devices, you benefit from:

- Reliable pressure measurement and high accuracy in hydrogen applications

- Complete portfolio of pressure transmitters available with gold-coating option

- Several decades of experience with hydrogen permeation barriers

- Bluetooth connection for convenient access to the device

Reliable temperature measurement in SMR and ATR processes

Steam methane reforming (SMR) is one of the most important and efficient processes for hydrogen production. In reforming reactors, methane is heated with steam to obtain a mixture of hydrogen and carbon monoxide after an endothermic reaction in the presence of a catalyst at high temperature (900 °C) and high pressure. Further process steps in hydrogen production involve a water gas shift reactor and Pressure Swing Absorbers (PSA).

Our expertise in the field

In autothermal reforming (ATR), oxygen and steam react with hydrocarbons to produce syngas. The process conditions are characterized by maximum operating temperatures between 900°C and 1200°C, strong thermal gradients in two zones filled with high-performance catalysts, and pressure of up to 80 bar.

Continuous monitoring of the operating temperature range is essential to achieve high plant efficiency and safety. By relying on Endress+Hauser temperature measurement devices, you benefit from:

- Robust, high-temperature thermocouples guaranteeing long lifetime thanks to innovative thermowell materials with increased wear and chemical resistance for continuous heat supply optimization

- A combination of

Improved flow measurement with Coriolis flowmeters

Hydrogen is the lightest gas that exists and at atmospheric conditions it has a density that is 10 times lower than natural gas. Since hydrogen streams have little mass to propagate sound and often exhibit high gas velocities, velocity-based measurement principles struggle to produce repeatable and accurate flow measurement results.

Our expertise in the field

Coriolis mass flow meters from Endress+Hauser can help you overcome these challenges:

- Coriolis mass flow meters do not use any of the gas properties as part of the measurement principle which makes this technology the preferred choice for hydrogen measurement

- Highest measurement sensitivity to achieve the widest mass flow measurement range

- Superior zero-point stability, can measure hydrogen at low pressure with the lowest measurement error in the market

Guided wave radar level measurement in CO2 storage tanks

With the deployment of CCUS technologies, large volumes of carbon dioxide are captured from industrial complexes to minimize emissions. CO2 can be transported in different phases and offers unique challenges due to phase changes. CO2 is primarily stored in liquid phase and transported via marine vessels for sequestration/permanent storage. Safety considerations are critical here considering the low temperatures of liquid CO2 and material handling.

Our expertise in the field

Liquid CO2 level measurement in storage and transportation tanks is challenging due to its low dielectric constant. Endress+Hauser

Capacitance level measurement for liquid hydrogen tanks

Liquid hydrogen (LH2) level measurement presents a challenging task due to the extreme cryogenic temperatures down to -253°C and operator challenges associated with handling this substance. There are different technologies in Endress+Hauser’s portfolio to measure those low temperatures: DP level measurement with impulse pipes is a classical solution in cryogenic applications, however, servo technology can also do the job as well as Endress+Hauser’s oldest technology: capacitance probes.

Our expertise in the field

Capacitance technology provides proven in use measurement in LH2 applications. The measurement is independent of the dielectric constant, vapors, temperature, and pressure changes, thus providing safe and reliable level measurement.

- Enhanced safety through proven capacitance technology

- Special insulation components and separate electronics make sure the cryogenic temperatures do not harm the devices

- Proven in use and suitable for use in small and medium stationary tanks