Major benefits of using steam as a heat transfer medium are that it is nontoxic, nonflammable, the equipment is inexpensive and requires little maintenance. Nevertheless, water hammer on pre-heaters, vibration, corrosion and erosion, reduced capacity of steam heaters, and overloaded steam traps can occur. As a result, you may experience system safety issues, early equipment failures, poor steam system efficiency, frequent boiler shutdowns as well as damaged steam pipes and valves.

Key facts

60 Mio $

Can be the cost of a 500MW steam turbine. If a revamp of the turbine is necessary, the encountered costs could be as much as the initial costs.

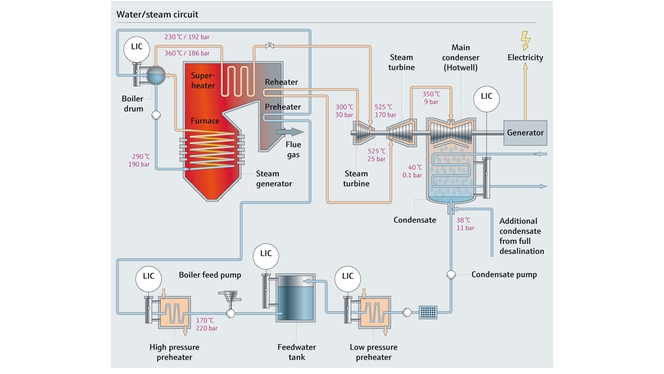

Increase the efficiency of the water/steam circuit

Condenser hotwell

The steam condenser’s main purpose is to condense the exhausted steam from the low-pressure turbine and convert it into water so that it can be reused in the boiler as feedwater. The vacuum and the temperature difference between cooling water and steam in the hot well is key to generating more power, but it also requires user-friendly monitoring and servicing as well as reliable level measurement at all times.

Our expertise in the field

To address vacuum issues and level gauge maintenance, try our Levelflex guided wave radar sensors as an alternative to traditional dp level transmitters and displacer type level.

- Save time and money with simple commissioning and trouble-free operation

- Use our Levelflex FMP51 to accurately measure level even under vacuum conditions

Steam (boiler) drum and pre-heaters

If the water level is too low, overheating of the wall tubes may cause accidents, leading to expensive repairs, downtime and injury to personnel. If the level is too high, boiler water carryover into the super-heater or turbine may lead to extensive maintenance costs, turbine or boiler outages, or decreased efficiency.

Our expertise in the field

Controlling the level requires high-end techniques, such as guided wave radar, as the level measurement must be accurate and transmitted to the control system. Use our Levelflex FMP54 to accurately measure level under extreme process conditions like high temperature and high pressure.

- Increase safety by reducing the risk of boiler shutdowns

- Increase availability by improved level control

- Rely on Heartbeat’s self-verification to ensure that the device is in a good shape

District heating and cooling

Whether in district heating networks, industrial utilities or large building complexes — boilers, tanks and pipe systems are being heated or cooled everywhere. The cooling and heating systems required for this frequently operate around the clock and consume a tremendous amount of energy.

Our expertise in the field

We offer an energy package that provides full transparency of how much energy is being consumed in a system and where.

- Improve accuracy and reliability of temperature measurement with our modular sensors

- Control flow with our ultrasonic and electromagnetic flowmeters

- Reduce CAPEX thanks to electronic pairing of temperature probes with thermal energy calculators EngyCal RH33 and EngyCal RS33

Benefits

With more than 60 years of application know-how in the field of water/ steam circuits, we help our customers optimize their life-cycle costs and reduce planning and procurement time. Our aim is to provide engineering solutions that are simpler, safe and accurate, and that bring consistent benefits to your plant process.

Key facts

25%

cost reduction with high-quality guided wave radar (GWR) level measurement in vessel bypass chambers

Key facts

1-stop

shop for complete assembly

Key facts

100,000

Levelflex bypass solutions installed worldwide

How we can help

We ensure the safe, efficient operation of your water-steam cycle and master vacuum and density problems that affect level measurement. We provide a complete range of technologies, solutions, and services to meet your requirements for different process parameters. Our measurement instruments are manufactured to the highest quality standards to guarantee consistent performance and compatibility.

- Increased efficiency and availability of your plant with improved level controls

- Reduced maintenance effort and life-cycle costs

- Reduced planning and procurement time

- Minimized loading and mounting costs (bypass chamber solutions with GWR)

- Full compliance with power plant safety standards (e.g. SIL, PED, ASME)