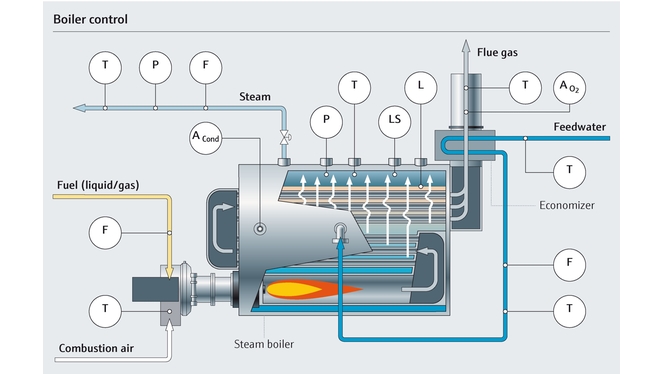

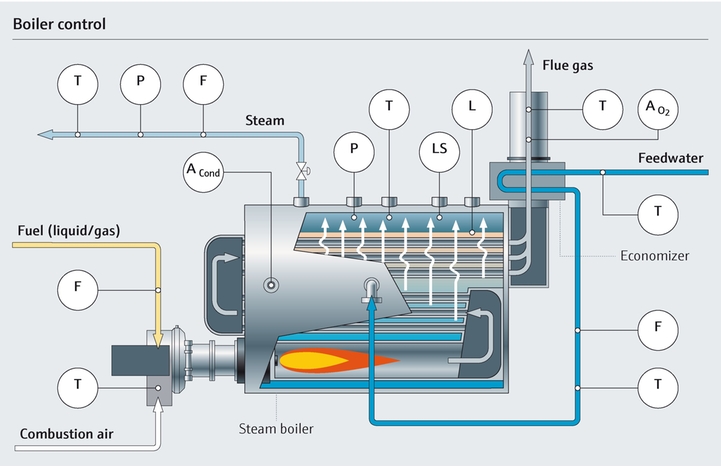

Boiler operation optimization is a key focus for utilities managers seeking production efficiencies. Steam remains a vital power source for industrial process heating, yet energy costs are spiraling. Competitive pressures make downtime and maintenance ever more costly, and so protecting boiler equipment and control systems is essential. With accurate and reliable measurement and monitoring fuel consumption can be optimized and boiler lifespan prolonged, unlocking considerable cost savings.

Klíčová fakta

50,000 $

představuje "až" dodatečné náklady za rok, s nimiž se můžete setkat v důsledku výpadků způsobených špatnou kvalitou napájecí vody.

Learn where to measure for a more efficient process

Steam application parameters

Feedwater preparation

A consistent supply of high-quality feedwater is not only vital to optimal boiler efficiency, it protects the boiler’s functional safety and longevity, avoiding equipment failures, costly blowdowns, and corrosion, ensuring consistent steam availability.

Our expertise in the field

Endress+Hauser metering and monitoring solutions deliver the essential information and insights to maximize feedwater quality and minimize boiler operating costs. Our Steam/Water Analysis System help you continuously check the quality of your feedwater.

- Measure feedwater flow with multivariable Proline Prowirl F 200 providing mass and energy output

- Monitor feedwater temperature downstream of the economizer with iTHERM TM131

- Extend boiler lifespan and drive steam production efficiency

Fuel combustion & exhaust

Efficient fuel combustion and compliant emissions are key objectives in boiler operation. If a boiler is burning fuel sub-optimally not only can cost losses be incurred, but emissions standards violated. Accurate measurement of fuel combustion and exhaust parameters is an essential but complex undertaking.

Our expertise in the field

At Endress+Hauser we provide adapted solutions for safe, efficient, and accessible fuel combustion measurement and exhaust management to maximize the performance of your boiler.

- Measure fuel flow with Proline t-mass 65F and fuel pressure with Cerabar M PMP51

- Measure combustion air temperature with iTHERM TM131 and flow with Proline t-mass A 150

- Comply with ASME Performance Test Codes (PTC 4-1998) for fuel-fired steam generators

Steam generation

An efficient, available supply of steam at the correct temperature is essential to effective utilities plant operations, meaning that appropriate boiler controls and a continuous flow measurement are, in turn, indispensable.

Our expertise in the field

Offering a full range of robust, proven flow metering and monitoring solutions, Endress+Hauser is also leading from the front with new technologies based on the multivariable (pressure and temperature compensated) Vortex principle. This technology enables wet steam detection or dryness fraction measurement, all combining to ensure superior overall boiler efficiency.

- Ensure accurate boiler controls for efficient steam generation

- Maximize fuel potential to drive cost savings

- Extend calibration intervals to minimize downtime with innovative Heartbeat Technology

Benefits

A deep understanding of your business and industry requirements lies at the heart of our product and service offering. You can rely on us to support you for improved steam boiler plant design, maintenance and operational productivity. We believe in serving before earning and this has been a principle that has shaped our company to this day.

Klíčová fakta

24/ 7

Operational safety throughout the entire life cycle of the steam system

Klíčová fakta

10 million

devices installed worldwide

Klíčová fakta

$73,000

annual cost savings after the installation of a control system that reduces the blowdown rate from 8% to 6%

How we can help

Endress+Hauser combines a broad instrumentation, service, and solutions portfolio with a profound understanding of energy and utility management to enable utilities managers to optimize boiler performance while protecting the fundamental integrity of equipment. Whether in ensuring the essential quality and supply of feedwater, evaluating flue gas, or determining the accuracy of measurement results we enable efficiencies to be gained and maintenance costs optimized.

- Rely on class-leading measurement technology, quality, and reliability

- Improve boiler house and plant efficiency whilst protecting safety

- Optimize maintenance with direct access to in-house expertise

- Comply with environmental protection and energy management standards